Ventilation systems in aviary houses today look much like those used in broiler houses. This means that requirements are higher, demanding more knowledge and better skills from everyone involved.

Climate technology in poultry houses

Modern climate technology comprises efficient fresh and exhaust air elements and a climate computer with various sensors. These sensors measure temperature, relative humidity, carbon dioxide and other important factors. All poultry houses should be equipped with such state-of-the-art technology, as this ensures ideal temperatures and a good air quality. The latter are necessary prerequisites for layers to show a stable and high laying capacity of more than 80 % into week 90 of their life. Weight, plumage and health also need to be on a high level.

In future, improving the air quality in barns will become even more important than it is today. Keeping layers with untrimmed beaks will require increased optimisation of all influencing factors; stress needs to be reduced. We have issues such as heat stress, cold stress and draughts under control, but dust and ammonia are still problematic and we have only just started finding solutions.

Wind chill

The ideal temperature (the technical term is “thermoneutral zone”) refers to the temperature range in which layers achieve their maximum biological performance while consuming the lowest amount of feed.

The ideal temperature not only differs based on weight and plumage of the birds, but also heavily depends on the relative humidity. The drier the air in the house, the more heat the birds dissipate by breathing and the higher the temperature should be in the barn. As a reverse conclusion, this means that the more humid the air in the house, the less heat can the birds emit by breathing, and the cooler the barn should be (see the table below). Exact temperature control therefore also requires a sensor that measures the relative humidity, in addition to the temperature sensor.

With increasing ventilation, air movements or air speed will become noticeable to the birds because their bodies lose more heat. This is called the wind chill. A more precise temperature control must thus consider the air speed in addition to the temperature and the humidity. Combined, these three factors influence how birds perceive the temperature, also called “apparent temperature”. Any modern climate computer should therefore be able to account for these factors.

Target temperature as a function of relative humidity | |||||

Target temperature |

Temperature in °C at ... % relative humidity | ||||

at 65 % RH |

40 % |

50 % |

60 % |

70 % |

80 % |

20°C |

25 |

23 |

21 |

20 |

18 |

21°C |

26 |

24 |

22 |

20 |

19 |

22°C |

27 |

25 |

23 |

21 |

20 |

23°C |

28 |

26 |

24 |

22 |

21 |

24°C |

29 |

27 |

25 |

23 |

22 |

Values applicable for windless conditions

Minimising ammonia formation

As a bird of the savannah, chickens are not influenced much by the relative humidity as long the temperature is fine. However, humidity plays an important role when dealing with manure drying, litter quality and concentrations of ammonia and dust in the air.

In aviary systems, most of the poultry manure drops onto manure belts, where it dries to have a dry matter (DM) content between 30 and 50 %, depending on how often manure is removed and how strong the manure belt ventilation system is. The air in the house absorbs the water vapour released from the drying manure, which significantly increases the relative humidity inside the barn.

All other manure (depending on the aviary, origin, light and feeding program, etc.) is dropped in the litter. The litter remains in the house for a much longer time. It should dry to have a DM content of 70 or 80 % to be considered “dry litter”. This process produces significant amounts of water vapour that need to be absorbed by the air. If ventilation is not sufficient, this means that the relative humidity inside the barn rises (> 70 and up to 80 %), promoting the formation of ammonia.

Problem: wet litter

Another problem caused by excessive humidity values is wet litter, which often occurs in the cold season and leads to increased ammonia formation. Litter always becomes wet when warm or too humid air (with a high dew point) hits colder surfaces in the barn, such as the floor or the litter itself, and condenses at these surfaces.

However, litter can also become wet without the air in the barn being the cause. For example when many hens defecate on the house floor early in the morning. The litter then becomes very dense and difficult to dry. The farmer should prevent this by using appropriate measures.

Too dry air and litter in the barn are not desirable either, as this can promote dust formation, with negative consequences on the respiratory tracts of birds and humans. Relative humidity should therefore remain between 50 and 65 %.

Stocking density and ventilation in the summer

Cage houses can keep two or three times more hens than aviary houses, i.e. stocking densities are much higher in cages. This leads to more heat from the birds, which in turn requires more ventilation. In the summer, a higher air change rate leads to higher air speeds and thus a higher wind chill factor.

In aviary houses or where birds are kept on the floor, stocking densities are much lower. Does this mean that ventilation can also be reduced? Not necessarily. Heat stress is a risk especially in the summer, when temperatures are high.

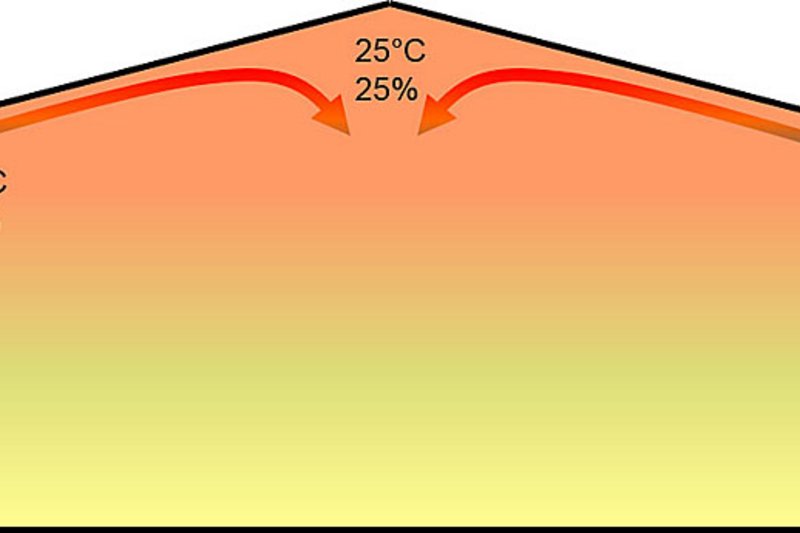

Tunnel ventilation

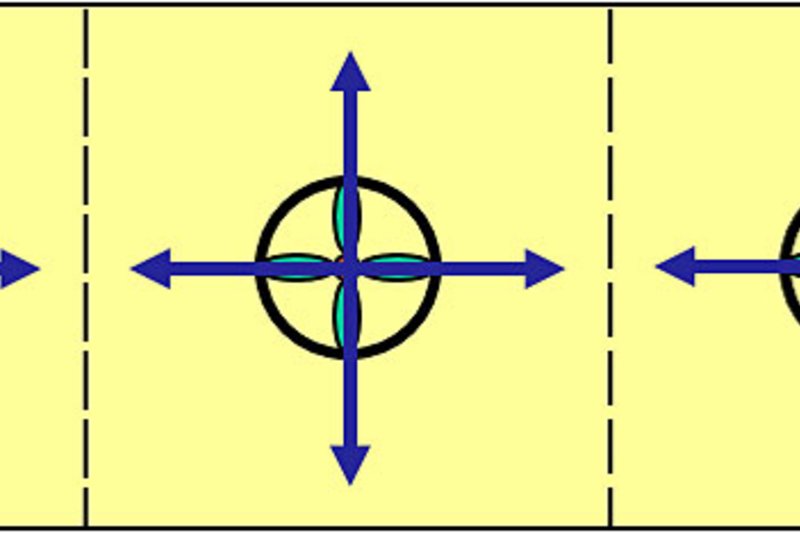

This issue can be solved quite easily by using a tunnel ventilation system (figure 1). However, air change rates per hen will be much higher than the 5.0 m3/h prescribed in DIN 18910. To create a strong, lengthwise airflow in the barn (> 1.0 - 2.5 m/s), air change rates between 9 and 10 m3/h per layer are common in the summer.

Centralised exhaust air removal via exhaust air towers or high exhaust air chimneys as they are often required in Germany is thus a very good basis for tunnel ventilation. The “only” other thing to do is creating large openings in the front gable wall or at the beginning of both side walls. Automatic shutters or very large wall inlets are popular for these openings. Tunnel ventilation systems must be regulated very precisely as the wind chill can turn a desired cooling effect into undesirable hypothermia. We call this a draught.

Stocking density and ventilation in the winter

A higher air change rate in the winter improves the air quality. In houses where birds are kept on the floor, however, the ventilation method for the winter is much more complicated. Hens should be active and scratch, fly/flutter, dust-bathe, visit the nest and consume sufficient amounts of feed and water.

For winter ventilation, the goal is a very low carbon dioxide (CO2) concentration in the house air, because CO2 causes tiredness and inactivity (as everyone working in an office can testify). The CO2 concentration should therefore be no higher than 2000 ppm. DIN 18910 mentions 3000 ppm. To stay below this value, minimum ventilation must be increased to more than 1.00 m3/h per layer. (In cage houses, values are usually only 0.50 m3/h.)

Higher minimum ventilation simultaneously means much less heat in aviary houses due to the lower stocking density, i.e. temperatures in the barn drop when the weather turns cold. Low temperatures in the house – less than 20°C are okay, but values should never fall below 12°C – are not dangerous for well-feathered layers, nor will they reduce the laying performance. This remains true as long as the birds ingest sufficient feed to produce the energy they need to balance their body heat. Unfortunately, this also means higher feed costs.

In addition to carbon dioxide, ammonia and water vapour also need to be removed from the barn. These factors may also lead to higher minimum ventilation. Especially in regions with very cold winters, heaters are therefore a sensible investment.

Ideal fresh air distribution

For efficient fresh air distribution, wall inlets, ceiling inlets or fresh air chimneys (depending on the barn and system type) can be distributed evenly for the entire bird area. These fresh air elements create jets of air that flow through the house at a high velocity, mixing quickly and completely with the air in the barn (figure 2). The air jets become larger and slower, thus creating the necessary air circulation. They heat up until they are as warm as the house, and lose humidity at the same time. Jets of fresh air should cover the entire space so all bird heat is utilized.

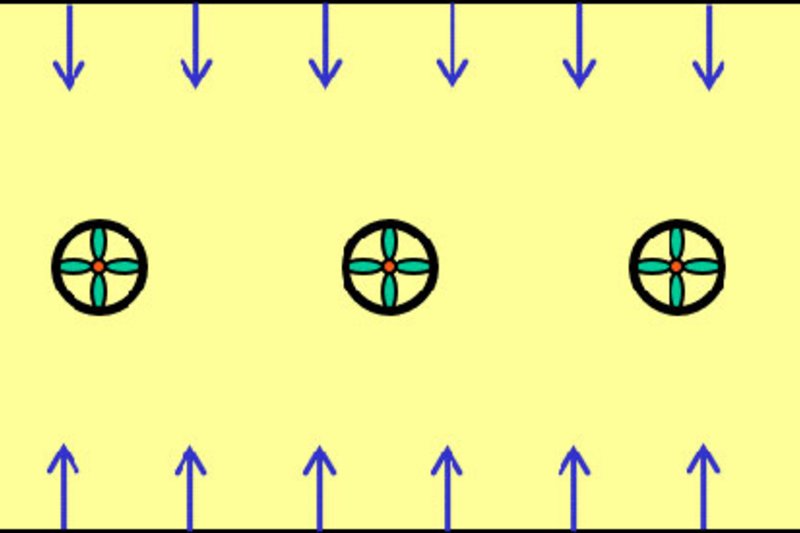

Wall inlets

Wall inlets (figure 3) are the best solution in barns where the system is installed evenly in rows. It is important that the inlets be incorporated into the side walls at a high place so that the cold fresh air flows above the system and the birds. The hens will not leave their usual place in the aviary just because of some draught, especially at night. This draught may cause secondary infections, however, for example with E. coli.

»»Advantage: fresh air enters directly from the outside, easy maintenance

»»Disadvantage: an additional light trap is required.

Fresh air from above

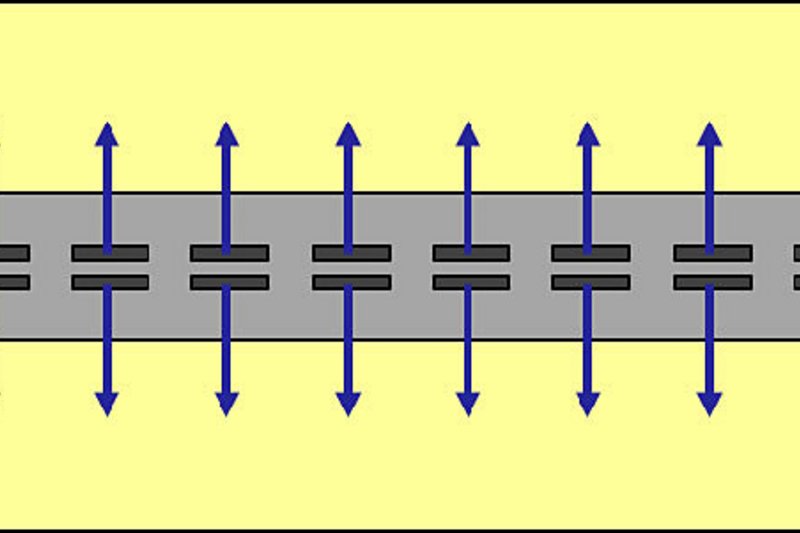

Ceiling inlets and fresh air chimneys are also very popular in Germany. We recommend them for all aviaries structured in such a way that the birds are more often located in the middle of the barn, with the scratching area situated near the walls. Heat is then produced not evenly, but mainly in the centre. To ensure that the fresh air mixes well with the house air, the fresh air should thus enter the barn centrally.

If ceiling inlets (figure 4) are used, the customer must provide an intermediate ceiling. The air in an attic is always warmer and thus drier than the fresh air entering a barn directly from the outside. This is an important advantage in winter. However, it can be a problem on hot summer days because temperatures rise too much, especially if only the ceiling is insulated and not the roof as well. Ceiling inlets should be completely closed in this case, with ventilation switched to tunnel mode.

»»Advantage: ideal positioning, no light trap required

»»Disadvantage: difficult maintenance upside down

Barns without intermediate ceiling need fresh air chimneys (figure 5).

Watching out for leaks

All ventilation systems discussed here are negative-pressure systems. This means that fans extract exhaust air from the barn, causing negative pressure. Due to this situation, the fresh air supply through the inlets can be controlled. There should be absolutely no leaks in the house for this to work, especially in the winter.

Windows, doors, exhaust air units that remain unused in winter, the manure cross channel and the egg collection system can all cause leaks in houses where barn eggs are produced. Do the test: add up all leaks and compare the result with the fresh air inlet of 0.50 m2 that is necessary for 10,000 layers in winter!

Unwanted air tends to enter either near the ground or to drop to the floor very quickly. In both cases, it has not warmed sufficiently. This reduces the air’s ability to absorb water vapour, causing the relative humidity to increase. The dew point also rises, and the result is wet litter.

A good but more expensive solution is installing fresh air chimneys with fans. These fans push the fresh air into the heat blanket below the ceiling in a controlled manner. The bird heat can thus be used ideally. The result is a balanced-pressure system that works even if there are leaks. Such a system especially makes sense in free range egg production, because a stable negative-pressure ventilation is nearly impossible to realise with pop holes.

Leaks have a very negative influence on the goal of achieving even ventilation and thus even temperatures, especially when exhaust air fans are installed centrally (figure 6). The first 25 to 40 % of the exhaust air chimneys should therefore be mounted along the entire house length when working with centralised exhaust air removal.

Ammonia concentrations and emissions

Ideal climate conditions in poultry houses not only support good temperatures and an ideal relative humidity in the barn for both humans and birds. They also ensure that the litter remains dry and that the manure dries well and fast on the belts, thus keeping ammonia concentrations low.

Today’s modern climate computers are already able to include the air’s NH3 content in their calculations. This requires a good and robust ammonia sensor (figure 7). An ammonia sensor measures the ammonia content in the house air so that ventilation can also be based on NH3 concentration.

Dipl.-Ing. agr. Jörg Bohnes

Big Dutchman International GmbH

DGS 44/2017