Poultry managers know of the risks connected to an infection with the avian influenza virus, and the high economic loss that can follow. In the German state of Lower Saxony alone, around 1.1 million birds had to be culled during the past winter season.

No entry for viruses!

Biosecurity in livestock houses

But not only poultry stocks need to be protected: German pig managers have been and still are heavily affected by the consequences of African swine fever. Suitable protective measures are necessary to keep the virus away from pig stocks.

Biosecurity starts with access control to the barn. However, even the strictest security protocols will fail if unauthorised persons enter the barn.

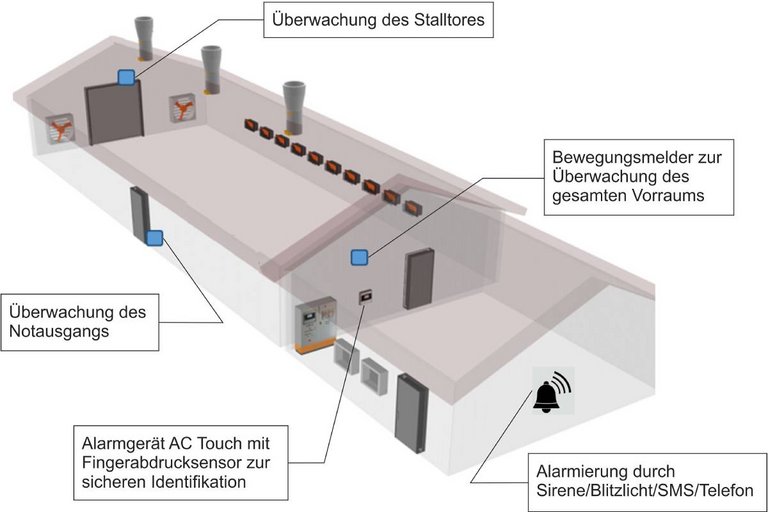

Digital alarm systems can help. At specific times or after the staff leave the barn, these systems arm automatically. They use door sensors and motion sensors to detect persons in the barn or in the service room and prompt anyone inside to identify themselves at the alarm unit using their fingerprint. The provided fingerprint is then compared to fingerprints in the system’s database.

If the person cannot be identified or ignores the prompt for identification, an alarm is generated, activating a warning horn or a warning light, making a phone call or sending an SMS as required to notify the farm manager or a person authorised for security questions. A log file is available to check later on who entered the barn and at which time.

In the past years, fresh air filtration has become one of the most important components of an efficient hygiene protocol, especially to protect valuable stock such as grandparents or breeders.

Mechanical filter systems minimise the amount of virus that enters the barn together with the fresh air. These systems are installed in front of the fresh air inlets so they can filter dust particles contaminated with virus. In the past, such filters have mainly been installed for pig housing to keep out the PRRS virus. Today, they are also used in poultry houses as a protection against H5N1.

When planning with fresh air filtration, equal and positive pressure ventilation systems have proved their worth. Compared to traditional negative pressure systems, these systems have higher investment costs, but provide the best protection for the animals. In contrast to negative pressure systems, no unfiltered air can enter the barn through undetected leaks.

Of course this does not mean that combining fresh air filtration with a negative pressure system is not possible. Quite the contrary: it is only the risk of unfiltered fresh air entering the barn that is higher.

There are different solutions available for effective fresh air filtration. For example, small and individual filter units per wall inlet are an option when using decentralised fresh air distribution, or large modules for centralised fresh air distribution. Even modular filter banks that can be integrated into the building are possible. Especially the latter option allows creating ventilation systems that work with both decentralised and centralised fresh air distribution.

The fans for the ventilation system must be selected based on the filters. They not only need to be able to withstand the additional differential pressure caused by the filters, but should also have a sufficient reserve to compensate for clogged filters. Energy-efficient fans are therefore a must.

However, filters with a higher class also increase the initial pressure loss of the system, i.e. energy costs rise. Additionally, recurring costs for filter replacement must be taken into account: the filters are loaded with particles during operation and need to be replaced before the maximum permissible differential pressure is reached. We recommend monitoring the differential pressure so the filters are always replaced in time.

If the filter class or quality is too low, the system might not provide sufficient protection or even fail. The worst-case scenario is a contamination of the stock.

Like any other climate component, the filter system needs to be integrated into the climate computer. When using a negative pressure ventilation system, only the additional pressure loss must be observed as well as a monitoring tool integrated. Positive pressure ventilation, however, requires an intelligent control. Its aim should be reducing the share of unfiltered fresh air in the barn to an absolute minimum. This is an exacting requirement for the climate control system, since it needs to provide permanent positive pressure.

If for example an exhaust air fan is activated, the computer has to react quickly and adjust the fresh air fans. The same applies when staff open a door or when an error occurs, for example a failing fan. This sounds simple, but if the control behaviour does not react perfectly to every little change, ventilation can be too high or too low, preventing the ventilation system from reaching the target value.

Fresh air filtration is a complex topic and incurs additional costs. Despite these costs, the number of filtration projects is increasing worldwide. In addition to Russia, South America and China, more and more customers from Europe plan or implement hygiene protocols that include fresh air filtration.