Egg collection systems

Flexible, efficient and gentle on the eggs

Egg collection systems are an integral part of the equipment in layer and breeder houses. This is mainly due to the following:

- reduced time and labour costs;

- excellent egg quality;

- accurate recording of all eggs produced.

Big Dutchman egg collection systems meet even higher requirements:

- gentle transport of the eggs;

- high reliability;

- easy handling.

Based on the farm size and layout as well as the individual customer’s requirements, Big Dutchman offers different options for egg collection. The product range includes elevators and lift systems as well as curve, rod and vertical conveyors, table drive systems and manual collection tables.

EggTrax

The EggTrax egg belt drive transfers the eggs gently from the longitudinal egg belt (nest) to any connected egg collection system. The reinforced drive unit operates at a speed of 2.6 m/min and is available in different egg belt widths of 245 mm, 350 mm, 400 mm and 500 mm.

Main advantages

- the unit can be removed, thus facilitating cleaning with a high-pressure washer;

- anti-crack “fingers” provide a light pressure on the eggs, which ensures a controlled transfer to the cross belt;

- tension-adjustable stainless steel wire threads guarantee a smooth transfer of the eggs while simultaneously allowing feathers, dust and soft-shelled eggs to fall down between the threads.

Vertical conveyors

Vertical conveyors are the standard solution whenever there is little space between the nests and the cross collection. They operate at a gradient of 50° and are available in two widths: 350 mm and 500 mm.

Vertical conveyors are powered by a separate drive unit for a more flexible collection speed. Big Dutchman recommends frequency-regulating the longitudinal egg belts (optional).

Rod conveyors

Rod conveyors are often used to connect the nest with the cross collection. They can only be used in a straight line. The rods are made of small, stabilised plastic tubes that are connected by a roller chain on both ends.

The distance between the rods is small enough to prevent even smaller eggs from slipping through, despite possible gradients of up to 25°.

Lift systems

Lift systems can be used for nests with multiple levels. Eggs are collected simultaneously per level in all rows. The lift system transports eggs especially gently as there is only one transfer point.

The production system is fully accessible because once all eggs have been collected, the lift moves into its parking position, which can be at a height of more than 2 m. Another advantage is that the lift requires only little space in the end set area.

Lifts can also automatically collect eggs mislaid in the system, so-called “system eggs”. For improved hygiene, lifts should be installed in the service room.

EC elevator

The EC elevator is able to collect large numbers of eggs. Especially in multi-level houses (up to three levels), the elevator can be equipped with an extra wide elevator chain and is thus an efficient egg collection system: it does not require much space and collects up to 15 000 eggs per hour.

A new feature is the option for “system egg collection”: the elevator can simultaneously collect eggs mislaid in the system. All belts either run into the elevator in parallel or system eggs are collected separately.

EggSort

EggSort ensures maximum smoothness during egg transport because there are virtually no transfer points. The longitudinal egg belt runs over the table, which means that no additional drive units are needed.

Simple manual collection tables (without drive) are mainly used for small units or if several houses are planned but not yet finished. If this is the case, a manual collection table is installed until it can be replaced by a cross collection.

Main advantages

- ideally suited for the manual collection of eggs;

- standard drive speed: 2.6 m/min, optionally VarioSpeed;

- available for different egg belt widths (2 x 200 mm, 245 mm, 350 mm, 400 mm and 500 mm);

- integrated egg belt brush for clean egg belts;

- robust and fully galvanised design for a long service life.

EggSmart

EggSmart is a new elevator from Big Dutchman that transports eggs from the longitudinal belts to the elevator chain and then onto the cross belt. It needs very little space in the end set area.

The eggs are first transferred from the longitudinal egg belt to a very short rod conveyor, from where deflectors distribute them onto the entire width of the elevator chain. No additional distribution units are required. The well-proven Big Dutchman transfer unit then transfers the eggs from the patented elevator chain to the cross belt.

Main advantages

- collection capacity of up to 9 000 eggs per hour;

- simultaneous collection of eggs from up to four tiers;

- little space required in the end set area;

- no distribution units, i.e. minimum maintenance and adjustment requirements;

- no synchronisation between rod conveyor and elevator chain necessary;

- easy access to all cage rows, no obstructions because of the cross collection;

- rod conveyor with cleaning function: dirt and soft-shelled eggs do not reach the elevator chain;

- use of high-quality chain modules;

- suitable for all cage types;

- simple installation.

EggCellent

The EggCellent elevator, designed by Big Dutchman, is characterised by its large collection capacity and requires only minimum system adjustments. Of course, it also provides everything necessary for a safe egg transport. This means that the eggs are first transferred from the longitudinal egg belt to a rod conveyor, from where deflectors distribute them onto the entire width of the elevator chain.

No additional distribution units are required. To match the conveying capacity and the laying performance, egg belts and elevator chains are actuated separately.

Main advantages

- high collection capacity of up to 19 000 eggs per hour*;

- simultaneous collection of eggs from up to eight tiers;

- no distribution units, i.e. minimum maintenance requirements;

- rod conveyor with cleaning function: dirt and soft-shelled eggs do not reach the elevator chain;

- easy access to all cage rows, no obstructions because of the cross collection;

- suitable for all cage types;

- simple installation and adjustment.

* depending on the system type, the egg belt width and the speed of the longitudinal belt

Lift system

The lift system collects the eggs per tier and simultaneously from all rows. The main feature of the lift system is that the cross conveyor moves to the individual tiers to collect the eggs. Once it has collected all eggs, the lift moves into its parking position.

The lift system is a good and economic solution, especially for small units or individual houses, and when the eggs are not collected per flock. The eggs are transported very gently as only one transfer is involved between the longitudinal belt and the cross belt.

Main advantages

- smooth egg transport as there is only one transfer from the longitudinal belt to the cross belt;

- easy access to all rows because the lift system moves into a parking position after egg collection is completed, i.e. the cross collection is no obstruction;

- little space is required in the end set area;

- the lift system can be combined with any cross collection of any width.

Curve conveyors

Different farm layouts as well as differences in height often require individual solutions for egg transportation. Curve conveyors are commonly used for cross collection because, thanks to their flexibility, they can be adapted to any type of layout.

The core part of each curve conveyor is a galvanised or plastic-coated conveyor chain that consists of two hardened outer chains with weld-on cross bars on the same level. The eggs are thus transferred smoothly to the chain and do not accumulate along the inner radius of the curve.

Ultrasound cleaning unit

Big Dutchman offers two cleaning units, both available as stationary and mobile version, to clean reliably the entire curve conveyor’s chain from dirt and thus from bacteria, salmonellae and fungi. Both units use the ultrasound technology in combination with hot water and a special cleaning agent.

The compact cleaning unit can clean up to 200 m of chain before the basin has to be refilled, while the larger unit cleans chain sections of up to 600 m. Depending on the degree of contamination, multiple repetitions may become necessary.

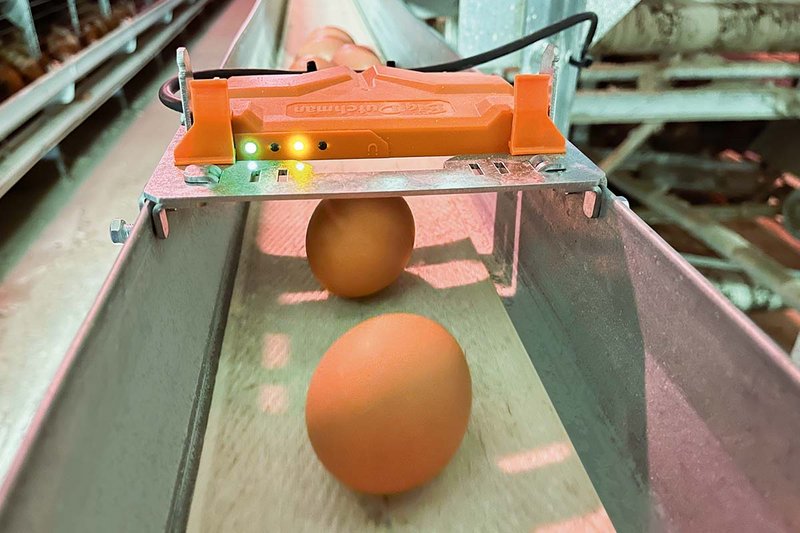

EggScan 120

The EggScan 120 egg counter offered by Big Dutchman records every egg with an accuracy of up to 99.8 percent. EggScan 120 has a scanning width of 120 mm (4.7 inches) and is thus ideal for smaller belts. The egg counter can be installed either at the longitudinal egg belt in every tier or at the cross belt. It is easy to integrate into the counter network using a “press & ready” plug.

Main advantages

- very accurate recording of all eggs on longitudinal and cross belts;

- works reliably in the dark due to infrared light;

- all data of the installed EggScan counters can be retrieved and compared with reference curves from breeding companies using ViperTouch or amacs;

- the optical system is easy to clean by removing the counter from the bracket without tools;

- robust technology, protection rating IP 69K.

Digital EggFlow

When using Digital EggFlow, the egg belt speed can be controlled based on the total number of eggs coming from the different houses. This makes it possible to optimally utilise the connected graders and packers.

Main advantages

- graders and packers are continuously loaded at full capacity;

- ideal egg quality thanks to a smooth and gentle transport of the eggs;

- automatic start of the belts in the morning; the egg flow stops directly at the packer;

- collection groups can be planned one day in advance;

- egg collection is completed simultaneously in all houses that belong to the same collection group – at maximum filling rates;

- Digital EggFlow allows the synchronisation of up to ten cross belts for up to four graders/packers.